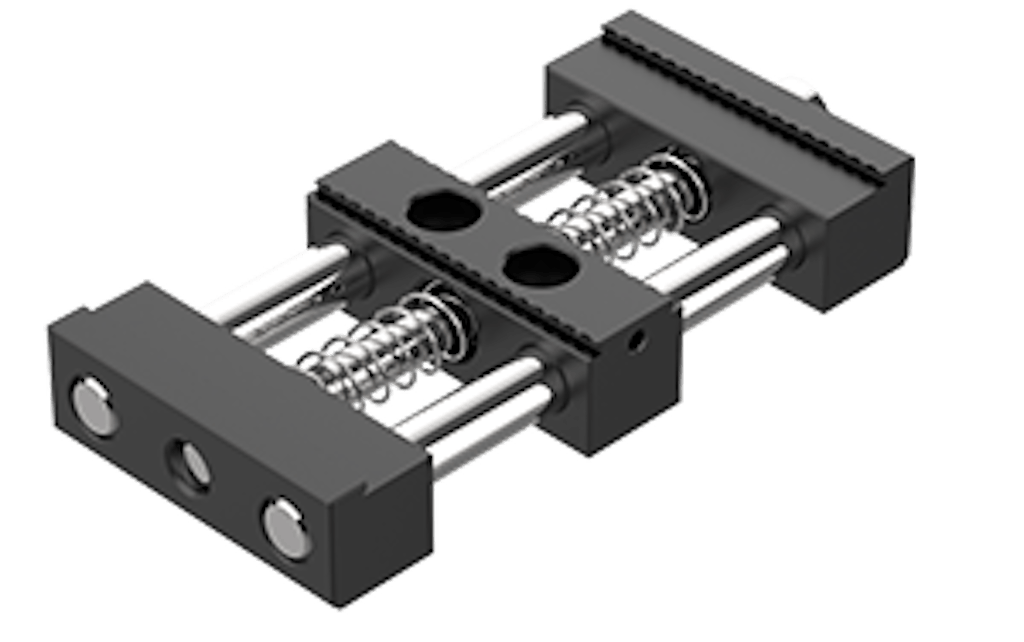

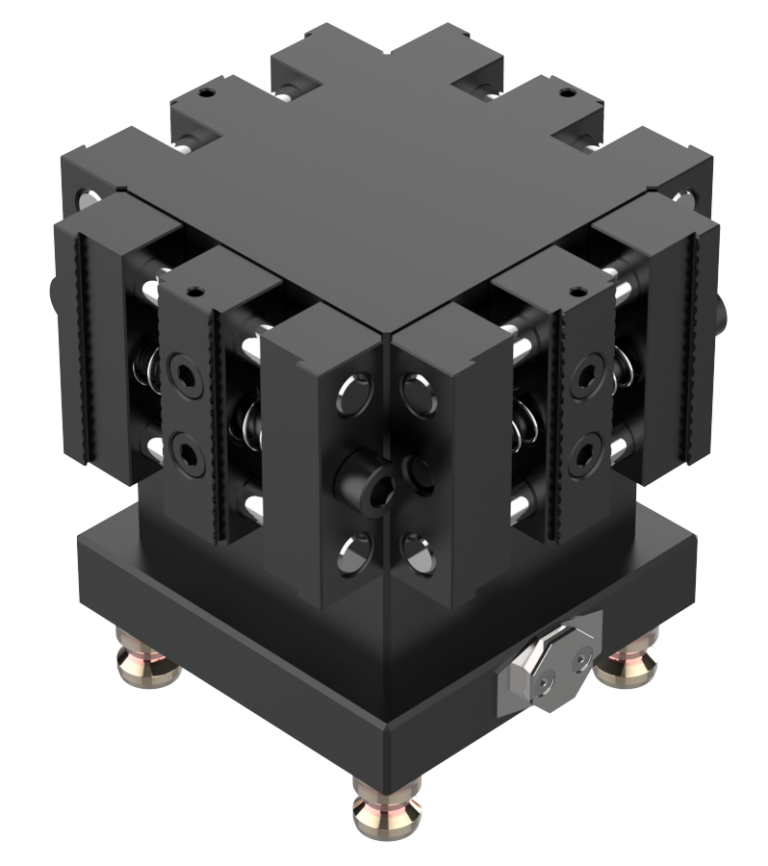

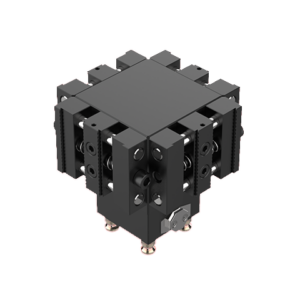

Pin Vise (75mm x 161.1mm x 25mm)

PV3X-6A $319.00- Elevate your craftsmanship with the 5th Axis Pin Vise.

- Precision tool designed for unparalleled control and accuracy.

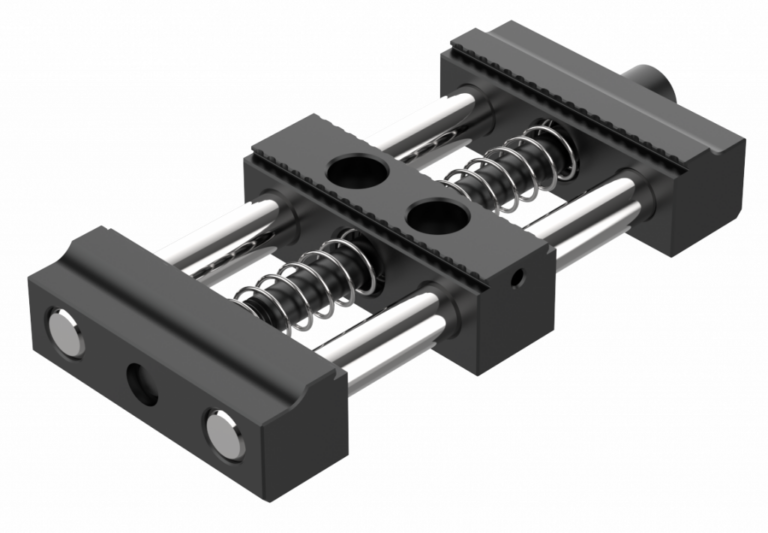

- Cost-Effective: High-precision, quality vises in a stripped-down design.

- Lightweight: Ideal for automated applications where weight is a consideration.

- Compact Design: The small footprint allows you to hold more parts per run for higher productivity.

Elevate your craftsmanship with the 5th Axis Pin Vise – a precision tool designed for unparalleled control and accuracy. Crafted with meticulous attention to detail, this compact and versatile pin vise is the perfect companion for a wide range of projects.

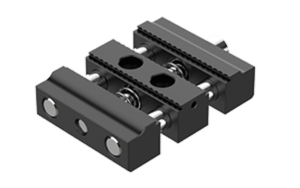

Cost-Effective: High-precision, quality vises in a stripped-down design.

Lightweight: Ideal for automated applications where weight is a consideration.

Compact Design: The small footprint allows you to hold more parts per run for higher productivity.

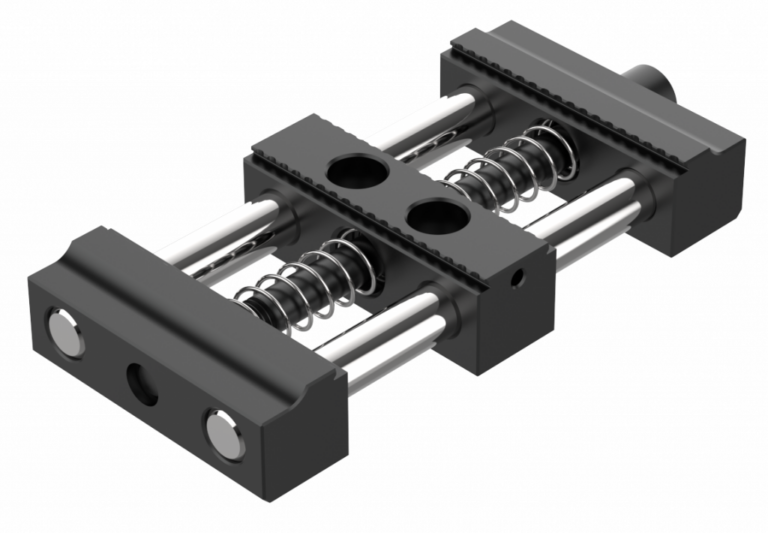

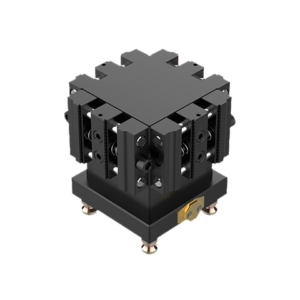

Size:

75mm x 161.1mm x 25mm

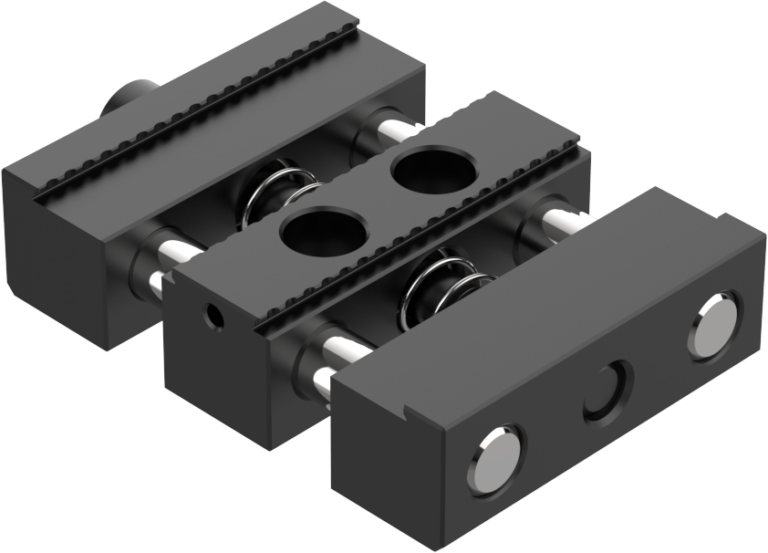

Jaw Width:

75mm

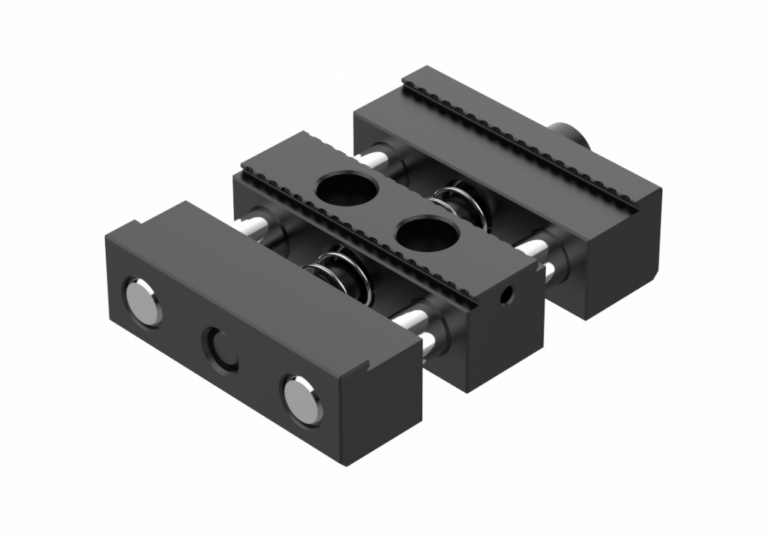

Clamping Range:

150: 1.85” – 2.25”,

130: 1.50” – 1.85”,

100: 1.00” – 1.40”,

MAX: 2.50” CUSTOMER PURCHASED HARDWARE,

*Off the shelf M12 SHCS can be purchased in varying lengths extend the clamping range.

Max Torque:

35 ft lb

Clamping Force at Max Torque:

3708 lbf

Note:

*PVX3-6A pin vises come with three different bolt lengths to provide different clamping range options.

Weight:

4 lbs

| File Name | Size | |

|---|---|---|

| 2D Drawing | 157 KB | Download Now |

| 3D Model | 760 KB | Download Now |

In stock