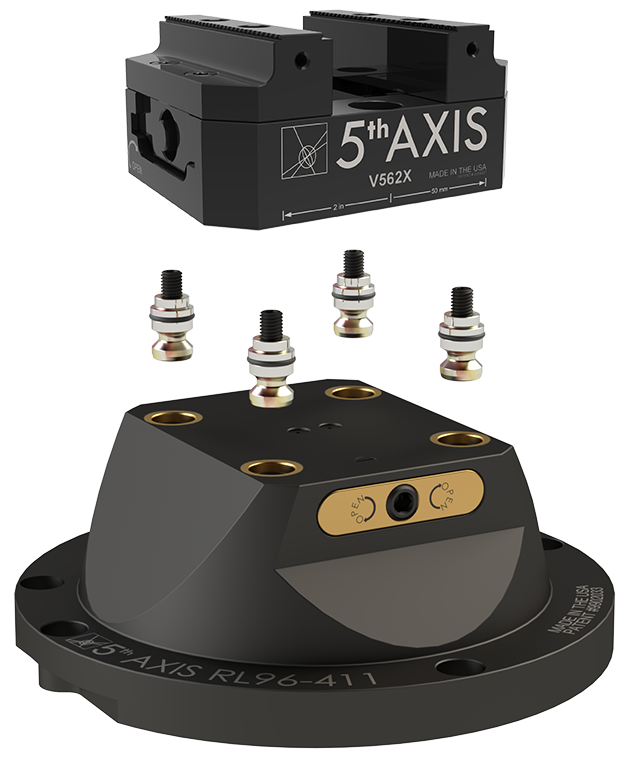

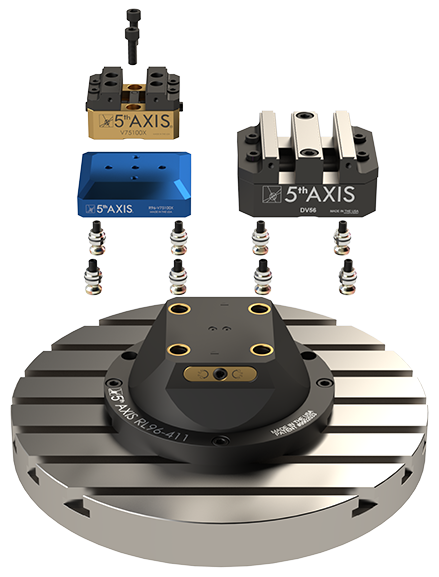

2x Small Self-Centering Vise Top Tooling

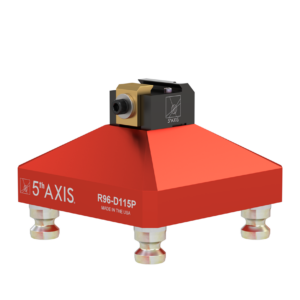

R96-2V75100X $2,449.00- Two V75100X self-centering vises on a 96mm compatible adapter.

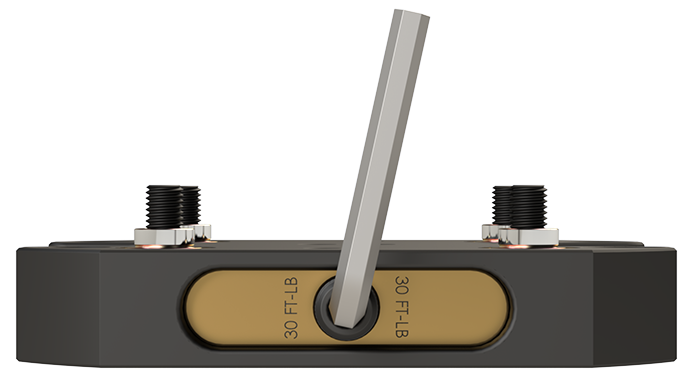

- Recent revision of the V75100 vise.

- 4-bolt jaw mounting for robust clamping.

- Sharper teeth for improved grip.

- Elevate machining capabilities with RockLock™ 96mm Quick Change System.

Invest in the future of machining with our 5th Axis RockLock™ 96mm Quick Change Top Tooling System. Stay competitive, boost your productivity, and achieve exceptional results in your machining operations. Trust in our commitment to quality, precision, and innovation, and take your machining capabilities to new heights today. The V75100X is the most recent revision of our V75100 vise. Now equipped with 4 bolt jaw mounting to reduce jaw lift providing robust clamping and sharper teeth for a better bite. This unit features 2x V75100X self-centering vises on a 96mm compatible adapter.

| File Name | Size | |

|---|---|---|

| 3D Model | 170 KB | Download Now |

| User Manual | 403 KB | Download Now |

| Dovetail Stock Prep | 170 KB | Download Now |

Only 2 left in stock (can be backordered)

FAQ

Consider your part size, machine table space, and automation needs. Use single-station vises for flexibility or double-station vises to maximize density.

No, 96mm top tooling is only compatible with 96mm RockLock™ bases. For 52mm systems, use the corresponding 52mm top tooling options.

The 96mm RockLock™ system provides ±0.005mm (±0.0002″) repeatability for high-precision applications.

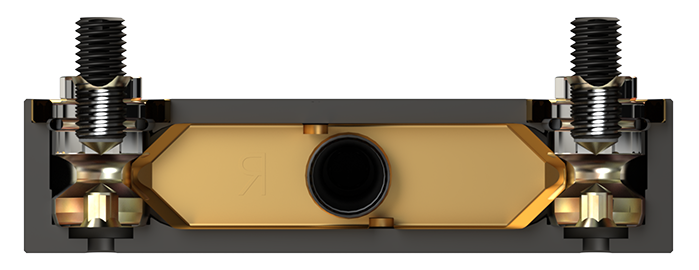

The pull studs and the quick-change base must be from the same manufacturer, but the top tooling is interchangeable. The 96mm spacing, counter bore and thread size are common between competitive systems.

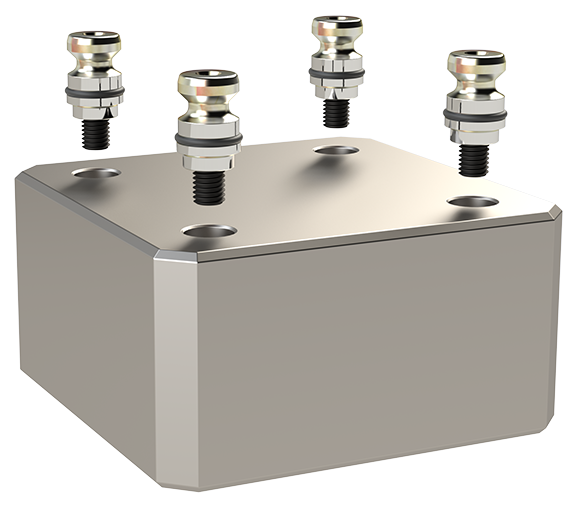

Replacement Parts

-

$899.00

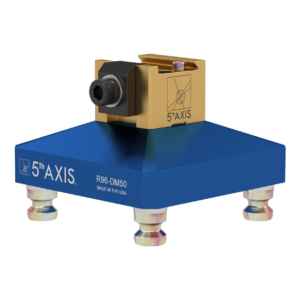

You May Also Like

-

$440.00

-

$440.00

No Comments yet!