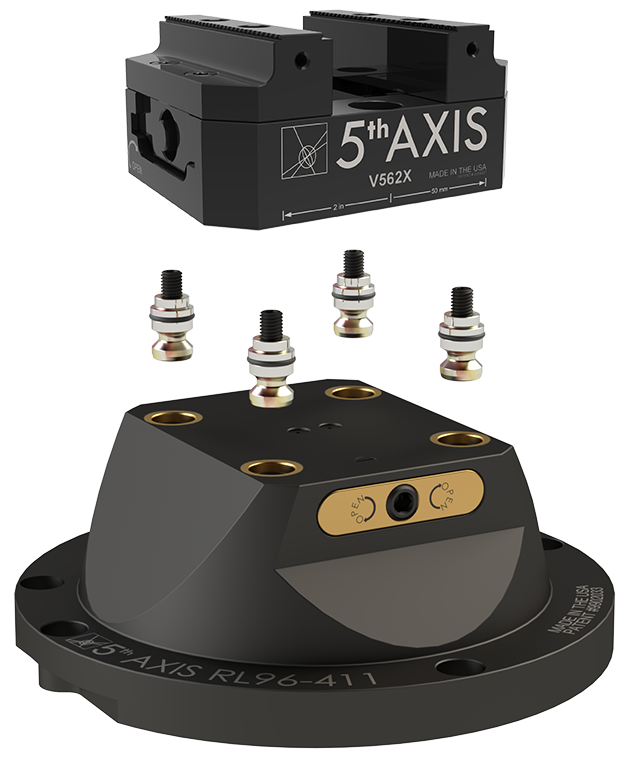

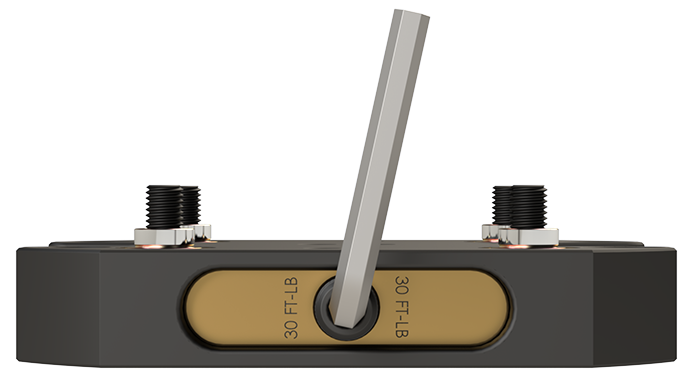

Medium Self-Centering Vise Top Tooling

R52-V75150X$1,089.00- Created to Meet Customer Demand

- Small Self-Centering Vise

- Increased Clamping Range Over the V75100X

- Base is 50mm Longer Than Standard V75100X

- Max Workpiece Size Increased from 76mm to 128mm

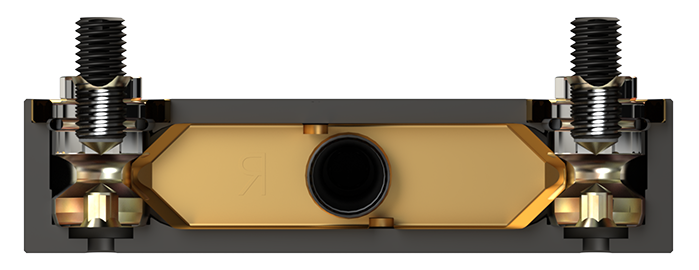

- 4-Bolt Jaw Mounting Design Reduces Jaw Lift

- Sharper Teeth Provide a Superior Bite in Raw Material

The R52- V75150X was created out of customer demand for a small self-centering vise with an increased clamping range over the popular V75100X vise. The base is 50mm longer than the standard V75100X, allowing the max workpiece size to increase from 76mm to 128mm. The new 4 bolt jaw mounting design reduces jaw lift and the sharper teeth provide a superior bite in raw material.

Size:

75mm x 150mm x 56mm

Jaw Width:

75mm

Clamping Force:

22.0 kN @ 60 Nm

Max Torque:

60 Nm

Clamping Range (Jaws Forward):

0 – 92.8mm

Clamping Range (Jaws Reversed):

38.5mm – 128.8mm

Shipping Weight:

7 lbs

Crate Dimensions (in):

8 × 6 × 7

| File Name | Size | |

|---|---|---|

| 3D Model | 133 KB | Download Now |

| Vise Dovetail Prep (1) | 1 MB | Download Now |

| V75150X Owner's Manual Rev. A | 505 KB | Download Now |

| Vise-Maintenance-Guide_REV_B | 438 KB | Download Now |

Only 1 left in stock (can be backordered)

Replacement Parts

- $1,019.00

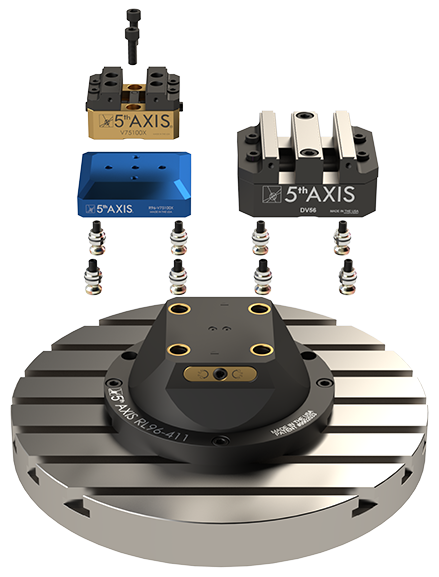

You May Also Like

- $440.00

- $440.00