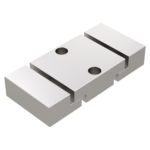

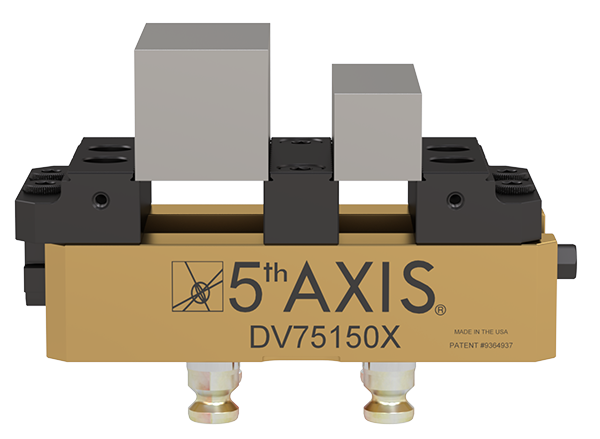

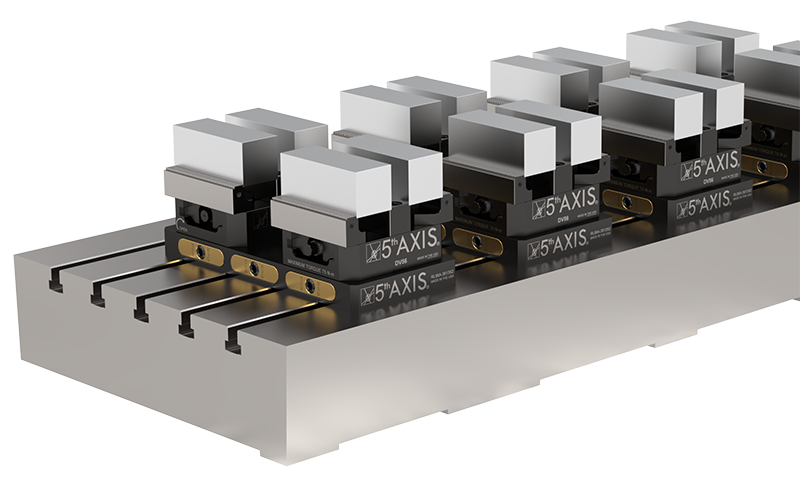

Small Double Station Vise (75mm x 150mm x 56mm)

DV75150X-J2 $949.00- Double station CNC machine vise designed for 3-axis CNC machines.

- Dual clamping stations double output without compromising precision.

- Engineered for quick setup and user-friendly operation.

- Ensures accuracy and tight tolerances for consistent results.

- Accommodates a wide range of workpiece sizes and materials.

- Robust construction for durability and reliability.

- Optimizes workflow by enabling parallel processing, reducing downtime.

When it comes to maximizing efficiency on 3-axis CNC machines, the DV75150X 3-Axis Double Station CNC Machine Vise stands as the epitome of precision and productivity. Designed with innovation in mind, this vise opens new avenues for machining excellence, ensuring that your operations are as efficient as they are accurate.

Key Features:

Double Station Advantage: With two clamping stations, the DV75150X allows you to secure two workpieces simultaneously, effectively doubling your output without compromising precision. Streamline your production process and reduce downtime between setups.

Three-Axis Compatibility: Engineered specifically for 3-axis CNC machines, this vise perfectly complements the capabilities of your equipment, offering seamless integration and optimal performance.

Rapid Clamping: The DV75150X is engineered for quick and easy setup. Its user-friendly design ensures that you can load and secure your workpieces in a matter of seconds, getting your machining process up and running swiftly.

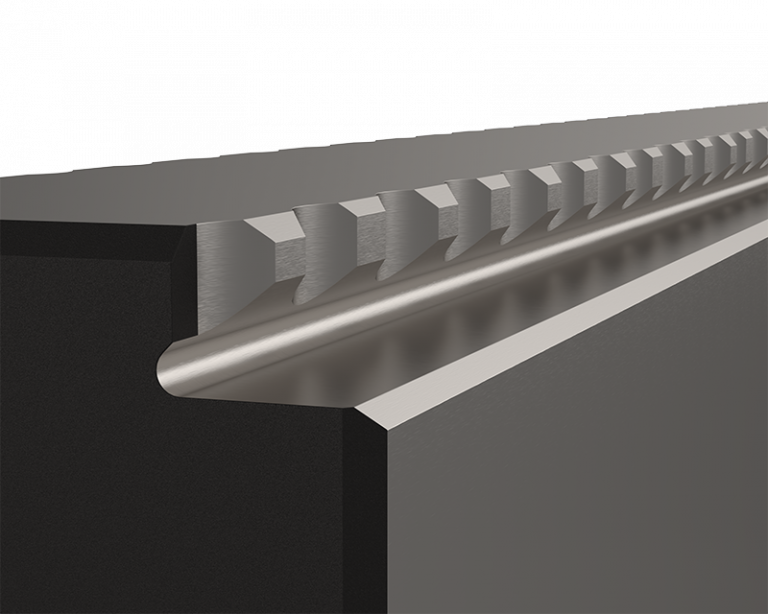

Precision Redefined: Crafted with meticulous attention to detail, this vise ensures accuracy at every turn. Achieve the tightest tolerances and consistently excellent results with a vise that leaves nothing to chance.

Versatile Workholding: The DV75150X’s adaptable jaws and multiple clamping options accommodate a wide range of workpiece sizes, shapes, and materials. Versatility is at the heart of this vise, ensuring that it meets the demands of various machining projects.

Durability and Reliability: Built to withstand the rigors of daily use, the DV75150X features a robust construction using high-quality materials. You can count on its longevity and reliability to support your machining endeavors for years to come.

Optimized Workflow: By enabling parallel processing of workpieces, the DV75150X not only increases your output but also enhances your overall workflow efficiency. Reduce idle time and maximize your machine’s potential.

| File Name | Size | |

|---|---|---|

| 3D Model | 4 MB | Download Now |

-

-

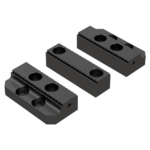

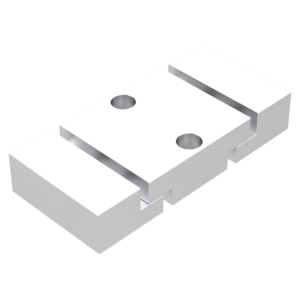

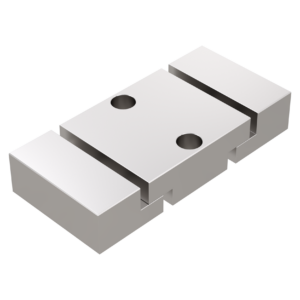

Hard Jaw Set (For DV75150X)

Hard Jaw Set (For DV75150X)$419.00

-

52mm Pull Stud (Single)

52mm Pull Stud (Single)$26.00

-

-

52mm Pull Stud Set

52mm Pull Stud Set$126.00

Only 1 left in stock

Replacement Parts

-

$159.00

-

$150.00

You May Also Like

-

$259.00

-

$419.00

No Comments yet!