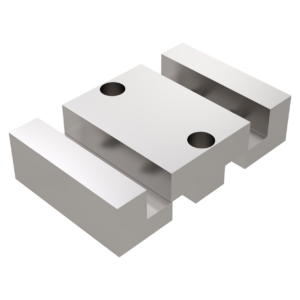

45° Dovetail Cutter w/ Inserts – Metric (25mm Shank Diameter)

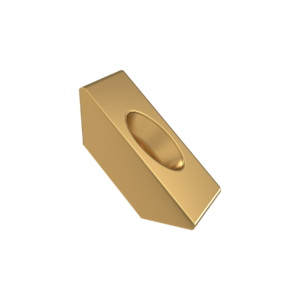

DC1750-M $440.00- Used to dovetail stock during prep

- 25mm shank for metric tool holders

- Replace inserts, not tools; indexable cutter extends tool life

- 45° cutting angle

- Includes 5 inserts

Dovetail Cutter(45 degrees) with 5 inserts (DC1750-B), 25mm shank.

| File Name | Size | |

|---|---|---|

| 2D Drawing | 90 KB | Download Now |

| 3D Model | 214 KB | Download Now |

| Speed and Feed | 1 MB | Download Now |

| Dovetail Troubleshooting Guide | 1 MB | Download Now |

In stock (can be backordered)

FAQ

Yes, we provide a comprehensive dovetail preparation guide with each size of dovetail fixture we offer at Fusion 360 Dovetail Stock

A 45-degree dovetail cutter is required to cut the necessary geometry to utilize the 5th Axis dovetail fixtures. We offer the only indexable dovetail cutter on the market, but any 45-degree carbide dovetail cutter will also work to prepare the stock.

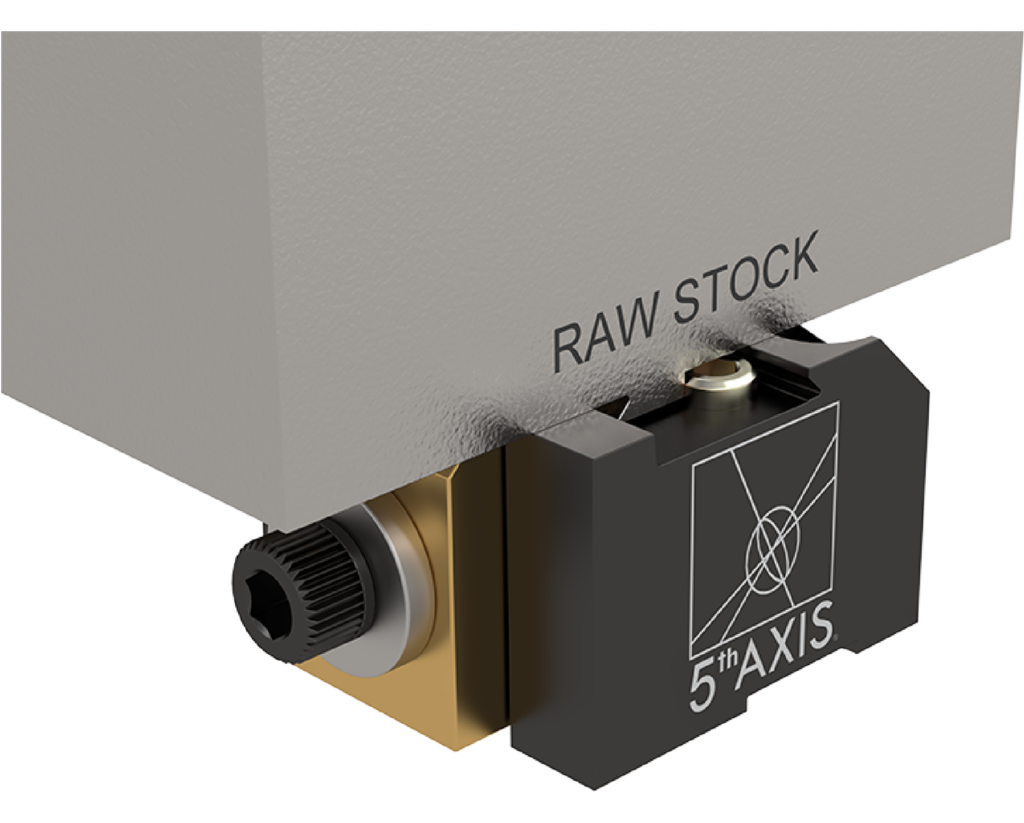

Dovetail fixtures are not built like a traditional machinist vise. More input torque does not equal more hold down force. The 45-degree angle drives a wedge to create a strong mechanical engagement between the fixture and the part, allowing for a secure grip with lower clamping force. This mechanical advantage allows parts to be held securely with minimum clamping force. Once the wedge is tightly clamped on the part there is not room for the stock to move.

The size of the dovetail fixture you choose is directly related to the size of your stock. Each dovetail fixture has a minimum dovetail width, and we always want the stock to be larger than the minimum dovetail width. The dovetail fixtures are completely modular, so as the length of the stock increases you can add additional dovetail fixtures for support as needed. Download the full stock preparation guide here:

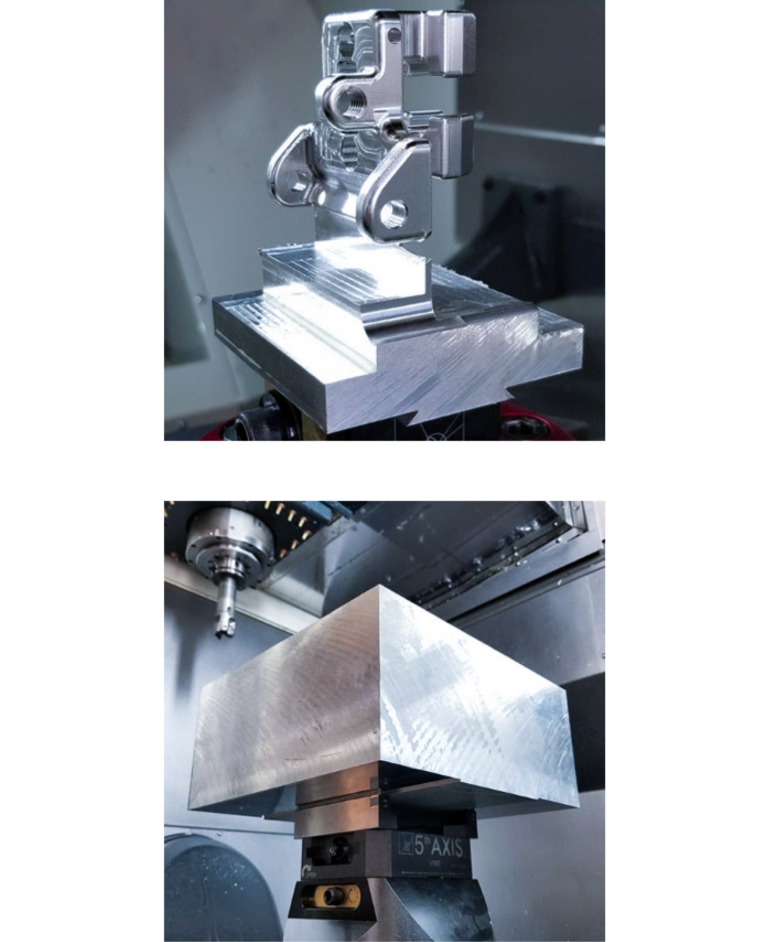

Selecting the right dovetail fixture depends on your stock size, material, and machining forces. The goal is to maintain maximum stability while minimizing material waste. As stock size increases, the need for additional modular dovetail fixtures grows due to physics—larger stock means more unsupported material, increasing the risk of deflection and vibration.

Understanding the Physics – Why Larger Stock Needs More Support

Overhang & Cantilever Effect

- As the stock gets larger, more material extends beyond the fixture’s clamping area.

- This creates a lever arm effect, increasing deflection and potential chatter.

- Solution: Use multiple dovetail fixtures to distribute clamping force evenly.

Machining Forces & Torque

- The larger the part, the more cutting forces and torque are exerted, especially during aggressive roughing.

- Without adequate support, vibration can reduce surface finish quality and tool life.

- Solution: More dovetail fixtures = better force distribution and reduced vibration.

Material Rigidity & Density

- Softer materials (aluminum, plastics) are more prone to bending and need additional clamping points.

- Harder materials (stainless, titanium) may withstand higher forces but require stronger, more stable clamping.

Weight

- Weight is not a critical factor. All dovetail fixtures are built from hardened tool steel. Ensuring you have the correct sized dovetail for your stock size is the most important factor.

Yes, click on the replacement part tab on the product page to see all available replacement parts.

Yes, dovetail fixtures can be used in an EDM. All 5th Axis dovetail fixtures are built from hardened tool steel. Most models are coated with PVD or black oxide. We recommend that customers who utilize dovetail fixtures inside the EDM do not leave them in the tank while not in operation. Properly drying the dovetail fixtures after they are removed from the EDM will prevent rusting.

We have the recommended torque values for all dovetail fixtures listed here:

Replacement Parts

-

$9.00

-

$21.00

No Comments yet!