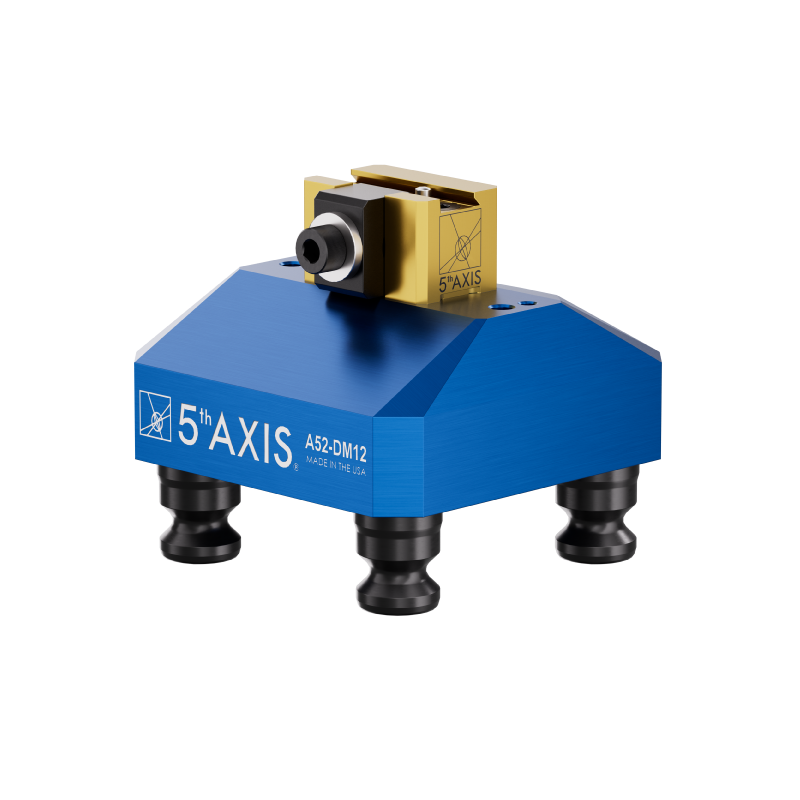

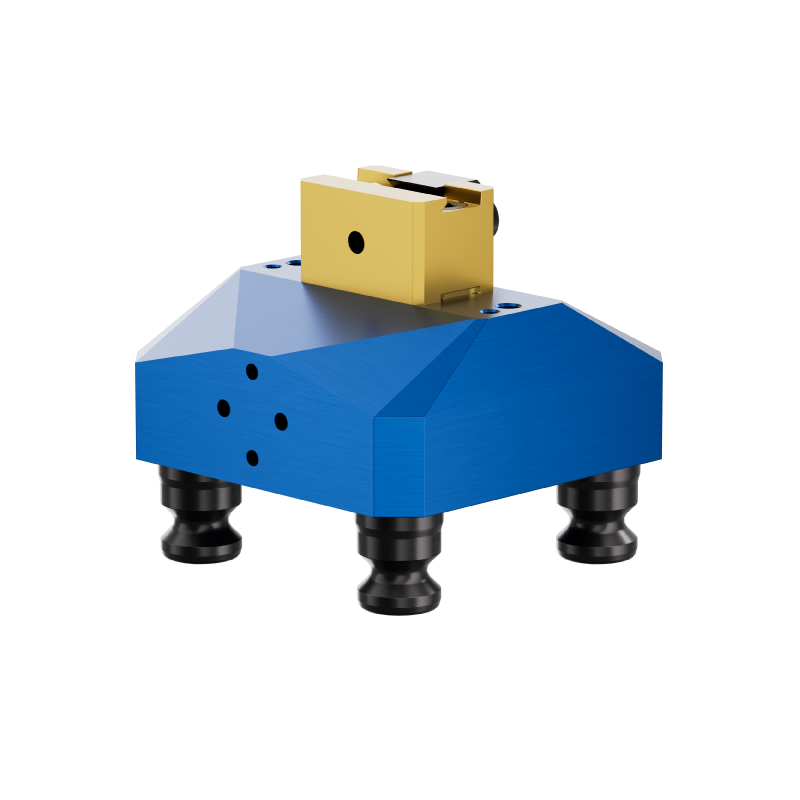

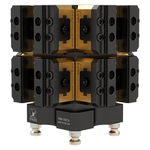

DM12 Dovetail Top Tooling

A52-DM12$812.00- Versatile and High-Performance 52mm Workholding Fixture

- Engineered to Elevate Productivity, Accuracy, and Efficiency

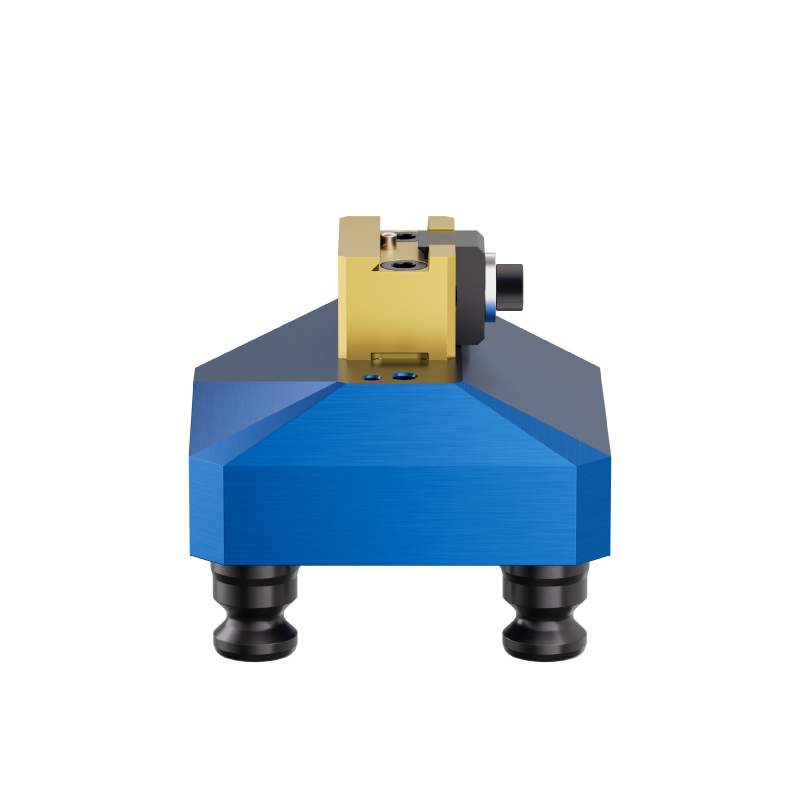

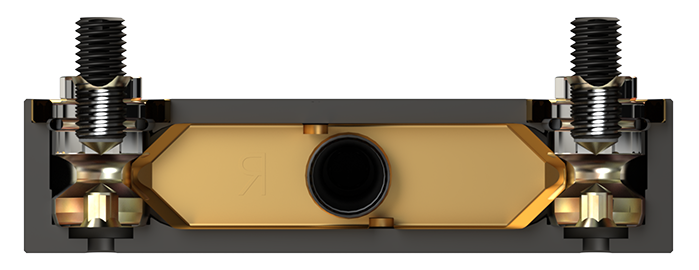

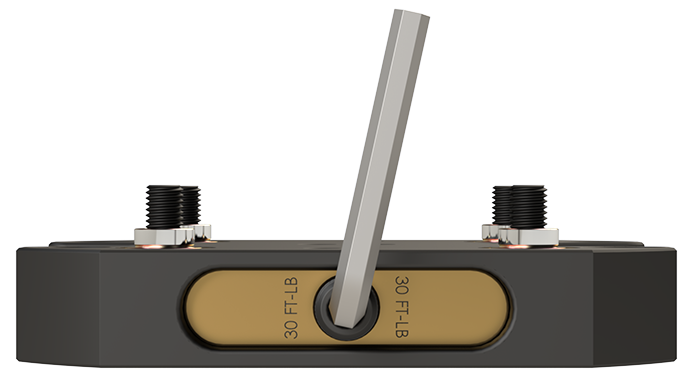

- Features a Wedge-Style Clamp for Superior Gripping Force

- Low-Profile Design Optimizes Tool Clearance

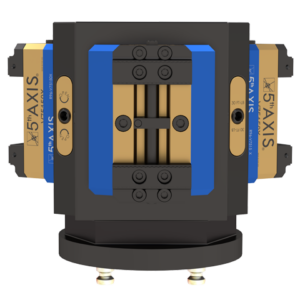

- Perfect for Multi-Axis Work on Smaller Parts

Introducing our versatile and high-performance 52mm line of Workholding Fixtures, designed to meet the demands of precision machining. Whether you’re a seasoned professional or just starting your journey in CNC machining, these fixtures are engineered to elevate your productivity, accuracy, and efficiency to new heights. The A52-DM12 is the smallest dovetail fixture in the 5th Axis workholding line. The A52-DM12 features a wedge style clamp for superior gripping force and a low profile design that optimizes tool clearance. This micro dovetail fixture is the perfect choice for multi-axis work on smaller parts.

| File Name | Size | |

|---|---|---|

| 2D Drawing | 113 KB | Download Now |

| 3D Model | 73 KB | Download Now |

| Dovetail Stock Prep & Troubleshooting Guide | 1 MB | Download Now |

Out of stock

FAQ

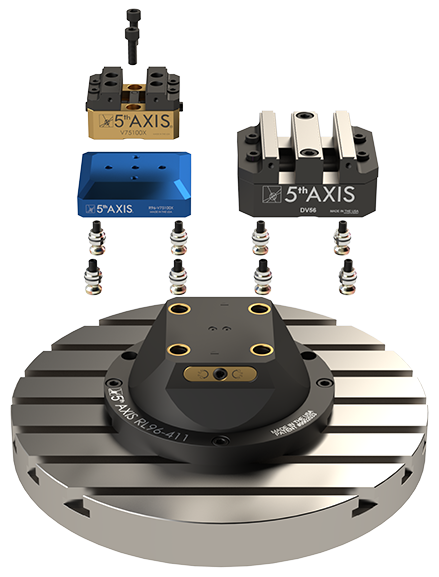

Consider your part size, machine table space, and automation needs. Use single-station vises for flexibility or double-station vises to maximize density.

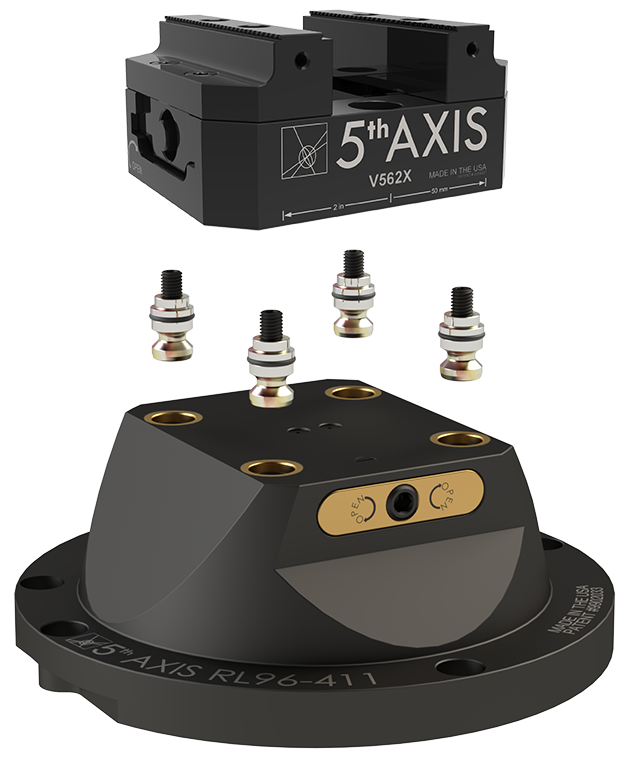

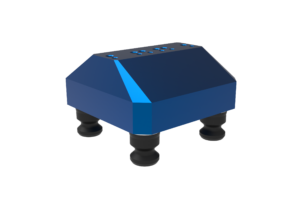

The 52mm RockLock™ system provides ±0.005mm (±0.0002″) repeatability for high-precision applications.

No, 52mm top tooling is only compatible with 52mm RockLock™ bases. For 96mm systems, use the corresponding 96mm top tooling options.

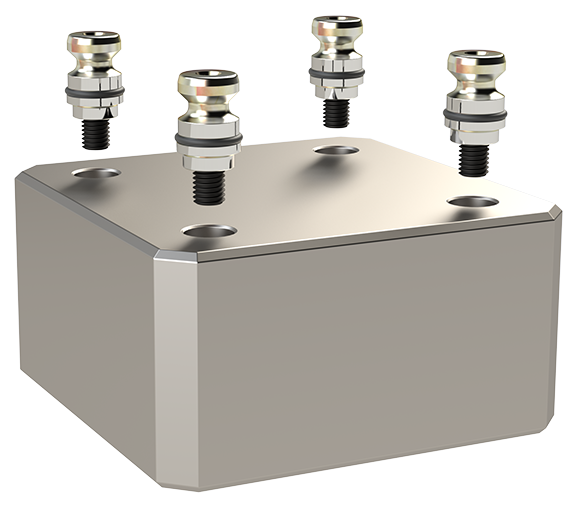

Replacement Parts

- $563.00

You May Also Like

- $440.00

- $440.00