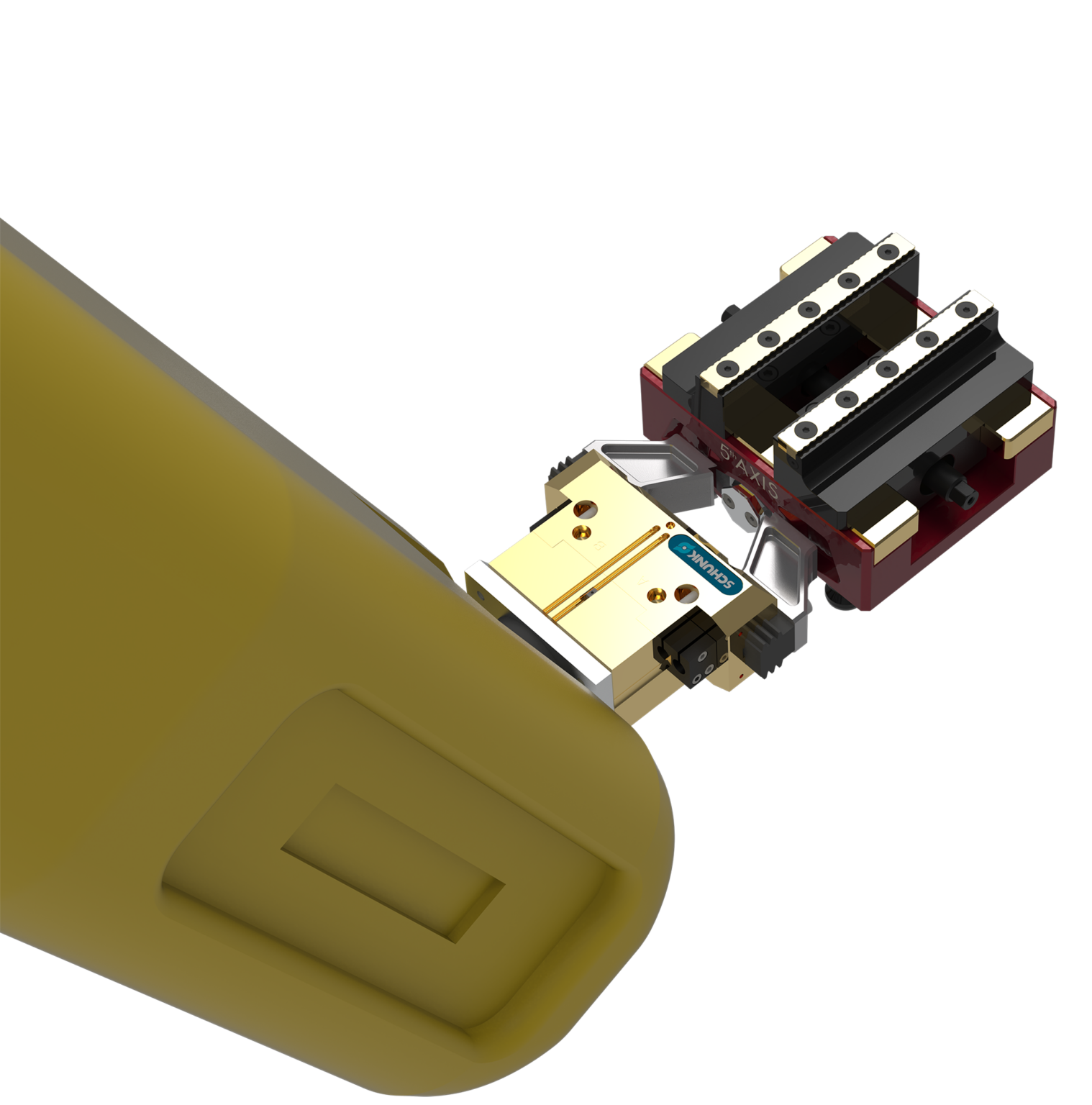

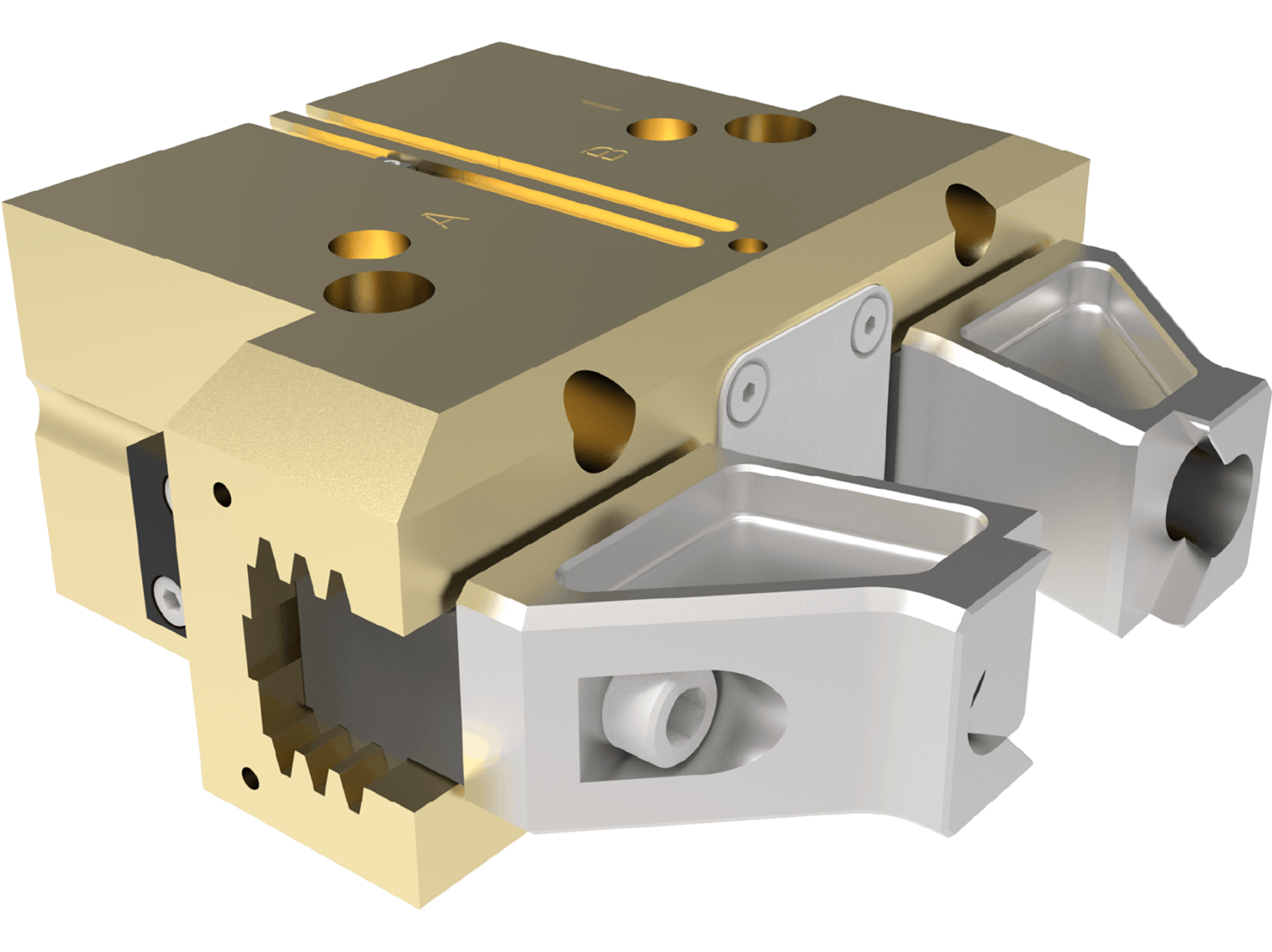

96mm Pneumatic Chuck (Side-Port)

RL96P-67B $4,499.00- 96mm pneumatic RockLock™ unit. (Side-Port)

- Working pressure range:

- 80 PSI (.55 MPa) MIN / 130 PSI (.86 MPa) MAX

- 96mm pull stud spacing

- Air to open / Spring to close

- Built for manual operation

- 1x port for clamp / unclamp

- No cleaning air / clamp confirmation

RockLock™ 96mm Pneumatic Chuck, Side Air Port

-

96mm Custom Gripper

96mm Custom Gripper$1,899.00

-

96mm Low Profile Cleat

96mm Low Profile Cleat$52.00

-

96mm Pull Stud (Single)

96mm Pull Stud (Single)$31.00

Only 7 left in stock (can be backordered)

FAQ

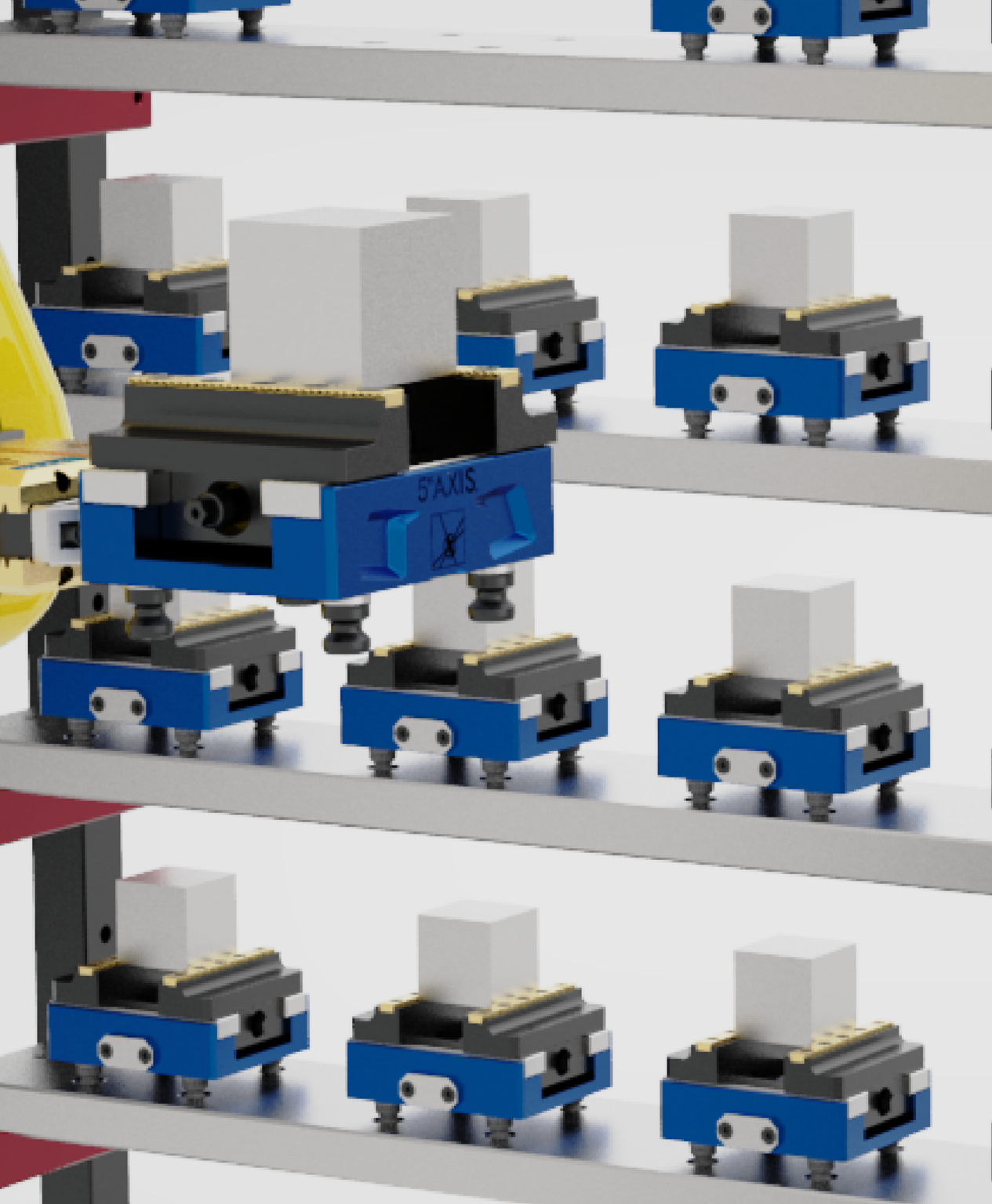

We offer a range of CNC automation solutions including quick-change tombstones, zero-point fixturing, pneumatic automation vises, and modular robot-ready workholding systems. Our products are designed to maximize spindle uptime and reduce manual intervention.

If you’re looking to reduce setup times, increase unattended machining, or maximize output per square foot, automation is a smart investment. Our systems are scalable, making them ideal for both high-mix/low-volume and high-volume production environments.

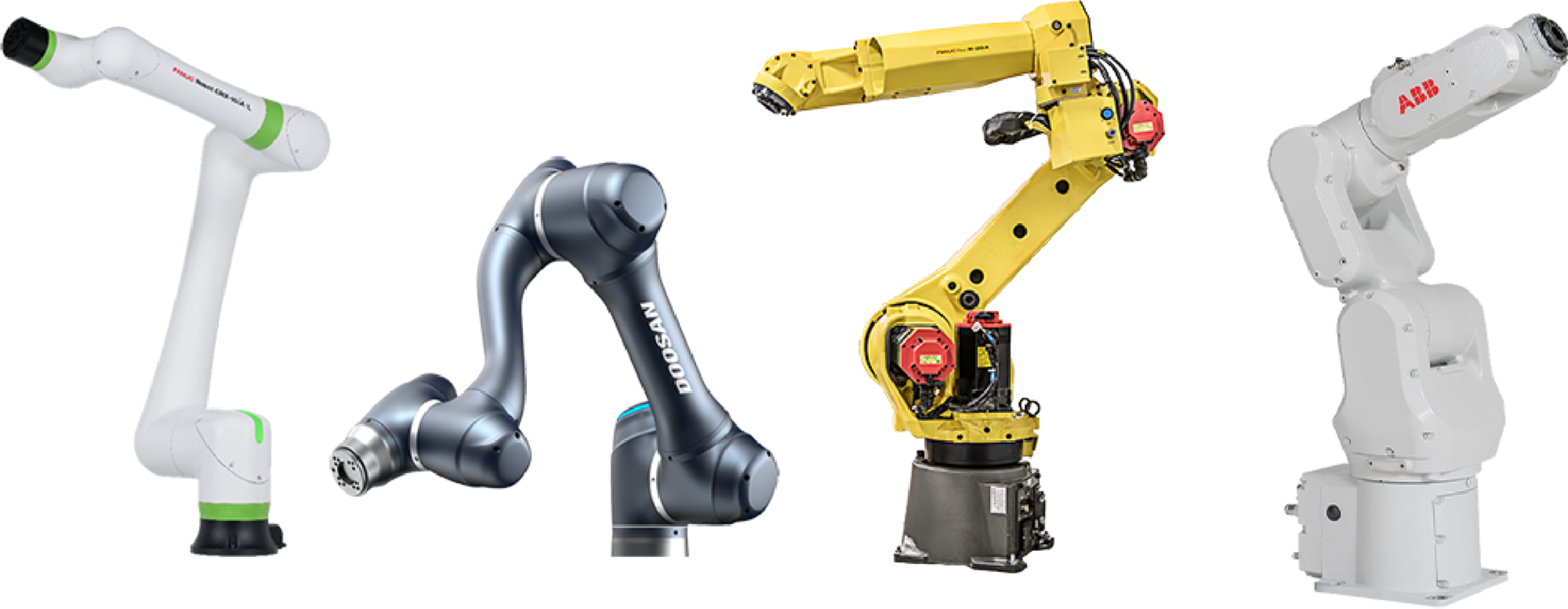

Yes. Our workholding is machine-agnostic and robot-compatible. We support a wide range of machine brands (Haas, Doosan, Mazak, etc.) and collaborative or industrial robot arms. Reach out and we’ll help confirm compatibility.

Precision, speed, and simplicity. Our patented RockLock™ zero-point system is trusted by top manufacturers for its reliability and repeatability. Every product is designed, built, and tested in the USA to meet the toughest shop demands.

No. While our systems are robot-ready, many customers start by using pneumatic vises and quick-change fixtures to improve manual processes before scaling up to full automation.

Absolutely. We offer automation-ready solutions for every machine configuration—HMC, VMC, and 5-axis. Our modular fixturing adapts to your setup.

Yes. Our team works with your integrator or directly with you to ensure the system is properly implemented. We also offer CAD models and technical documentation to speed up deployment.

Most shops see significant ROI within 6–12 months due to reduced labor, fewer setups, and increased machine utilization. The exact ROI depends on your volume and machine time costs.

Visit us at industry trade shows, explore our video gallery, or schedule a virtual demo with our team to see our automation solutions in action.

You May Also Like

-

$1,899.00

-

$31.00

-

$52.00

No Comments yet!