Get A Grip

With The New X-Series Hardware

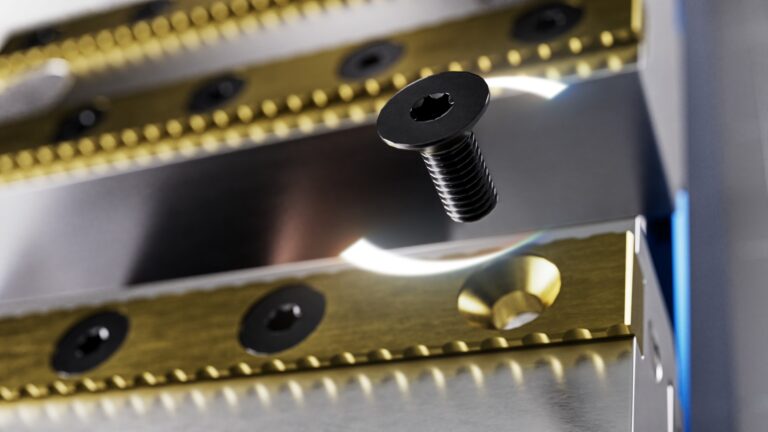

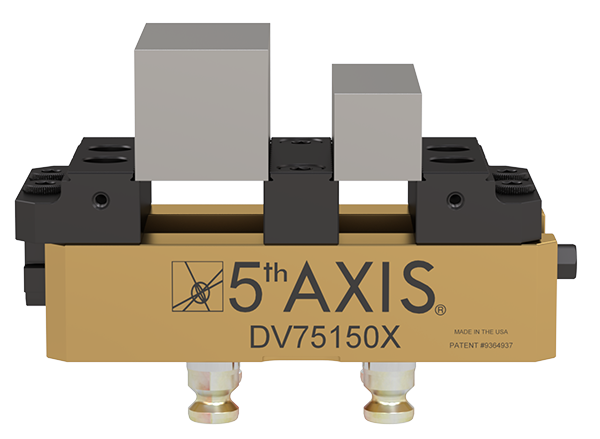

The X vises offer a 30% increase in clamping force and better overall rigidity. The 4-bolt jaw mounting system reduces jaw deflection while still allowing for reversible / quick-change jaw configurations.

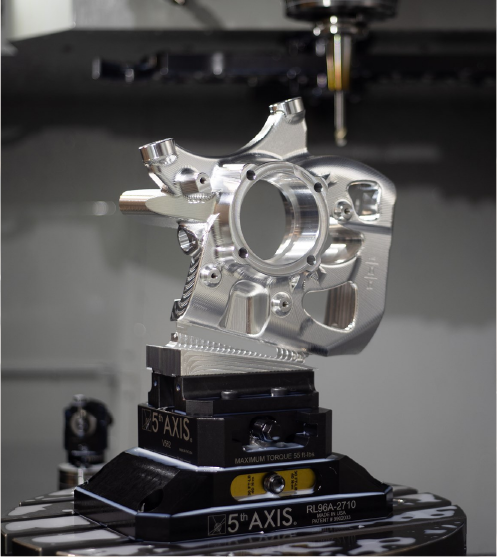

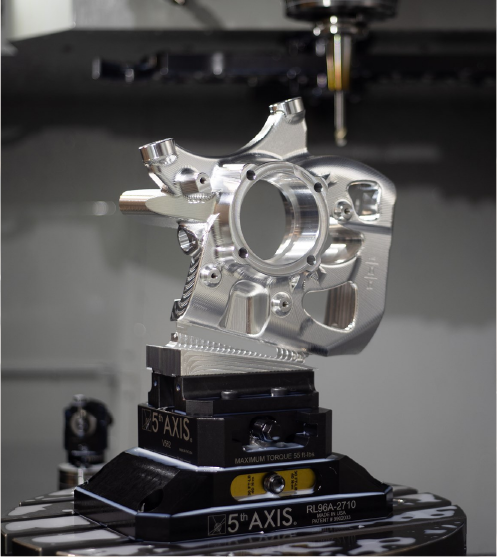

Built for precision and speed. From self-centering to dual-station designs, our CNC vises deliver rock-solid clamping, fast setups, and reliable performance for any job.

The X vises offer a 30% increase in clamping force and better overall rigidity. The 4-bolt jaw mounting system reduces jaw deflection while still allowing for reversible / quick-change jaw configurations.

22 KN – 25.1 KN

CLAMPING FORCE

4 bolt jaw mounting increased clamping force and rigidity by 30% compared to the original 2 bolt version.

Redesigned truck features a key and dowel pin for better accuracy and repeatability.

Overall height + width + length is the same as the original vise design. Vise mounting also matches the original design.

The X vises offer a 30% increase in clamping force and better overall rigidity. The 4-bolt jaw mounting system reduces jaw deflection while still allowing for reversible / quick-change jaw configurations.

Friction pins on the vise trucks allow for independent movement on the lead screw while still providing maximum clamping force.

Fit more vises on your machine table and watch your parts per cycle soar. Increase throughput, decrease tool change time and machine down time between operations.

The center jaw is the fixed position to ensure proper clamping no matter the conditions. Machine different parts on the same vise simultaneously, or simply negate small variations in stock size.

Superior Lightweight Design: Constructed from high-strength aluminum alloy with integrated steel rails, LiteVise™ offers the perfect balance between durability and portability.

4500lbs of clamping force in a compact footprint that weighs 50-70% less than traditional steel vises.