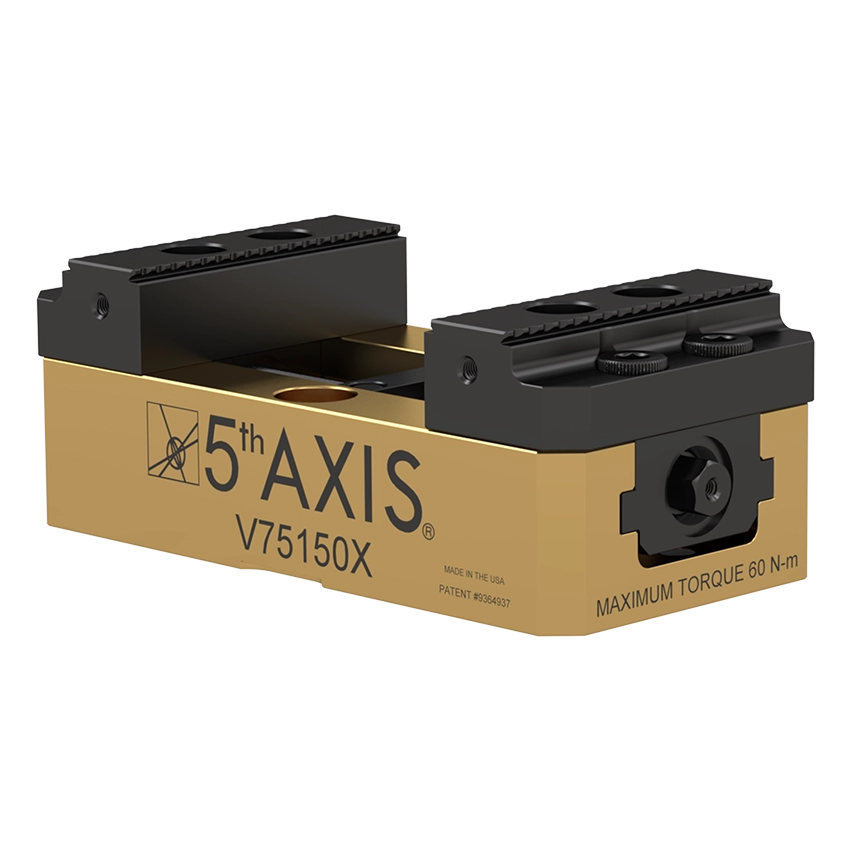

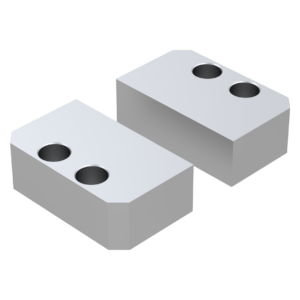

Compact Self-Centering Vise (75mm x 150mm x 56mm)

V75150X $1,019.00- Self-centering CNC machine vise with an extended clamping range.

- Patented self-centering mechanism for precise workpiece placement.

- Accommodates various workpiece sizes with a 3-inch jaw width.

- Quick-change feature enhances setup efficiency and durability.

Unlock a new dimension of precision and efficiency in your machining operations with the 5th Axis V75150X Self-Centering CNC Machine Vise. Engineered for excellence, this cutting-edge vise is your gateway to unparalleled accuracy, repeatability, and productivity in the world of CNC machining.

The V75150X was created out of customer demand for a small self-centering vise with an increased clamping range over the popular V75150X vise. The base is 50mm longer than the standard V75100X, allowing the max workpiece size to increase from 76mm to 128mm. The new 4 bolt jaw mounting design reduces jaw lift and the sharper teeth provide a superior bite in raw material.

Key Features:

Self-Centering Technology: The V75150X boasts an patented self-centering mechanism that eliminates the need for time-consuming manual adjustments. Simply load your workpiece, and the vise automatically centers and secures it with unmatched precision.

Versatile Workholding: With a generous 3-inch jaw width and a jaw opening capacity of up to 5inches, this vise accommodates a wide range of workpiece sizes and shapes, from small intricate parts to larger components, ensuring versatility in your machining projects.

Ultimate Precision: Crafted with meticulous attention to detail, the V75100x guarantees micrometer-level precision. Its robust construction, combined with high-quality materials, ensures minimal deflection, enabling you to achieve the tightest tolerances in your machining tasks.

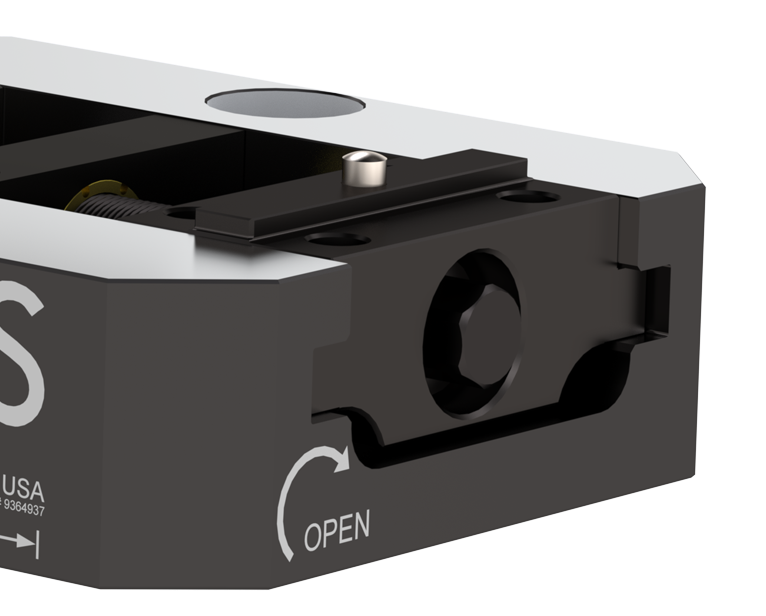

Quick and Easy Setup: Say goodbye to time wasted on tedious setup procedures. The V75150X features a quick-change design, allowing you to load and secure workpieces swiftly, reducing downtime and increasing overall productivity.

Durable Build: Built to withstand the rigors of heavy-duty machining, this CNC machine vise is constructed from premium materials and features a hardened steel body, ensuring long-lasting durability and reliability.

| File Name | Size | |

|---|---|---|

| 2D Drawing | 338 KB | Download Now |

| 3D Model | 443 KB | Download Now |

| V75150X Owner's Manual Rev. A | 505 KB | Download Now |

| Vise Dovetail Prep (9) | 1 MB | Download Now |

-

52mm Pull Stud (Single)

52mm Pull Stud (Single)$26.00

-

-

52mm Pull Stud Set

52mm Pull Stud Set$126.00

In stock (can be backordered)

FAQ

5th Axis Self Centering Vise is engineered for precision and consistency, delivering repeatability better than ±0.0005” (±0.0127mm). This level of accuracy ensures that every part is perfectly centered with no need for manual adjustments, making it ideal for high-tolerance 5-axis machining applications.

Precision-Ground Components – The vise body and jaws are hardened and ground to exacting tolerances, ensuring precise movement and alignment every time.

Dual-Lead Screw Mechanism – The synchronized lead screw system ensures that both jaws move evenly, clamping the part perfectly centered without deviation.

Aluminum and steel soft jaws are available for all models of 5th axis vises. The standard serrated hard jaws are built for Op 1 roughing operations. All clamping on finished surfaces should be done in machinable soft jaws.

Managing Jaw Lift – The 5th Axis Advantage

Jaw lift is a reality in every vise—regardless of manufacturer claims. It occurs when clamping force causes the jaws to slightly tilt or lift, leading to part misalignment, reduced clamping force, and inconsistent machining results. At 5th Axis, we’ve engineered our vises to minimize jaw lift and provide the most secure, repeatable, and precise Workholding available.

Precision-Ground Dovetail & Guideways

Our vises feature precision-ground contact surfaces and a robust dovetail design, ensuring that the jaws move smoothly while maintaining rigid, even contact.

Optimized Dual-Lead Screw Mechanism

The V562X and other 5th Axis vises utilize a dual-lead screw system to apply equal force to both jaws simultaneously, reducing uneven clamping that can amplify jaw lift.

High Clamping Force with Balanced Load Distribution

Our vises are designed to evenly distribute clamping force across the jaws, reducing deflection and ensuring better workpiece stability.

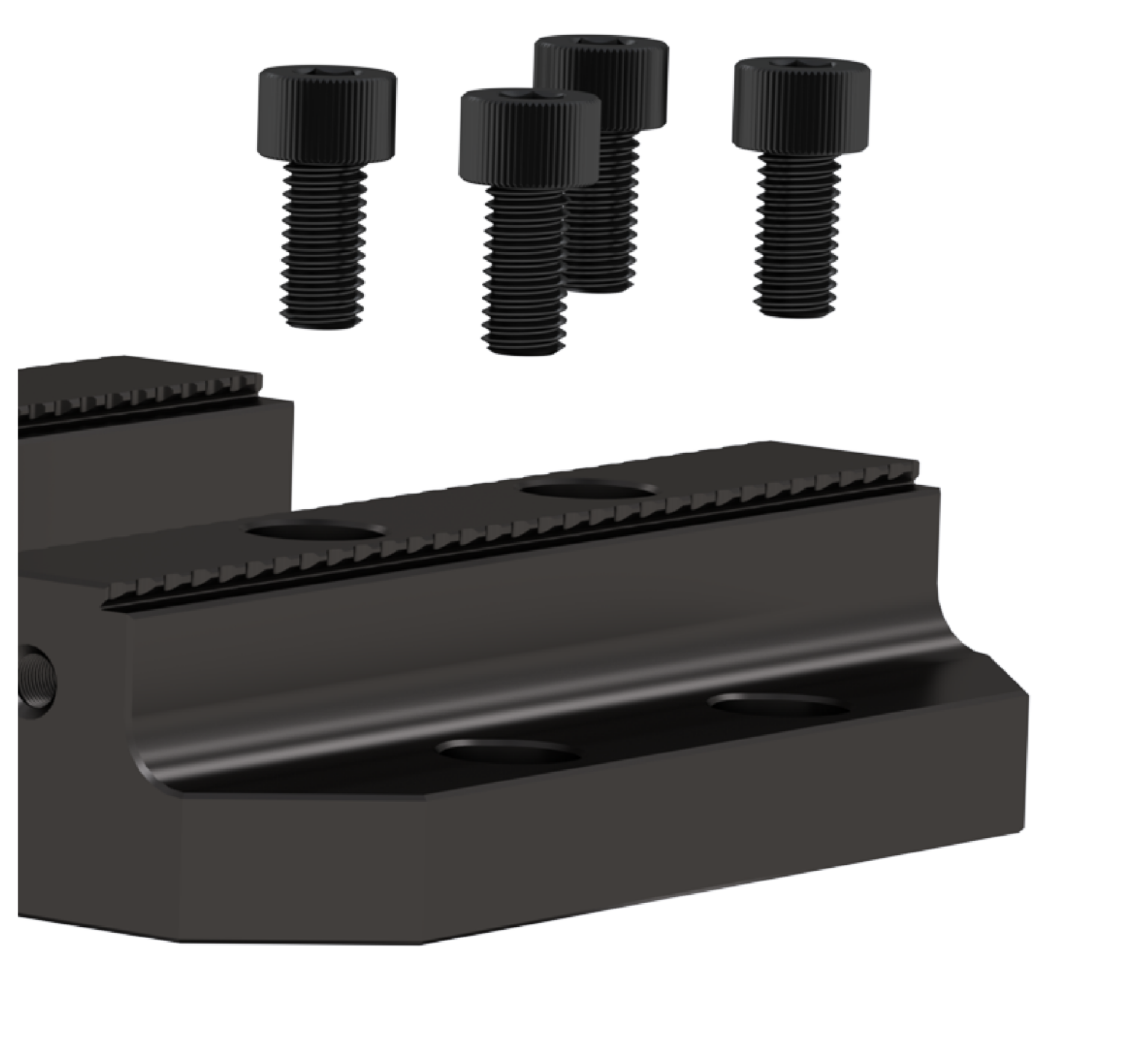

New four-bolt jaw mounting ensures jaws pull down under full torque. Hardened key way prevents jaw from twisting when torquing on your stock.

Finite Element Analysis (FEA) Testing

Every vise undergoes rigorous FEA testing to identify and minimize weak points, ensuring superior rigidity under load.

A standard 45-degree dovetail is built into the back of the standard hard jaw. This is an optional feature and will not get in the way if you choose not to utilize it. We recommend utilizing the dovetail when machining hard materials or where the stock size is larger than the opening of the vise itself.

The hardened serrated gripper teeth are built to bite directly into raw material. We recommend utilizing the serrated gripper teeth with for stock with a hardness under 35 HRC. For material with hardness over 35 HRC we recommend utilizing the dovetail or custom soft jaws.

Yes, the standard hard jaw features a smooth face, serrated gripper teeth and an integrated 45-degree dovetail. The standard hard jaws are built for Op 1 roughing and we highly recommend utilizing soft jaws for clamping on any finished surfaces.

5th Axis vises are compatible with all 3, 4 and 5-axis CNC machines.

Selecting the right self-centering vise is crucial for maximizing stability, efficiency, and machining accuracy. The right vise depends on your part size, machine type, and workholding needs. Check out our 3D configuration tool to find the best workholding for your application:

Key Factors When Choosing a Vise

Part Size & Clamping Range

V75100X (Compact 3” Vise) – Best for small to medium parts and tight machine envelopes.

V562X (5” Standard Vise) – Our most versatile option, ideal for a wide range of part sizes.

V510X (Large 10” Vise) – Designed for larger parts and heavier cutting forces.

Machine Size & Work Envelope

Smaller 3-, 4-, or 5-Axis Machines → Use a compact vise (V75100X, V75150X) for better tool access.

Larger Machines & Horizontal Setups → A larger vise (V510X) can handle bigger parts and aggressive cutting.

Material & Machining Forces

Light-to-Medium Machining (Aluminum, Plastics) → A smaller vise can typically handle the job.

Heavy-Duty Machining (Steel, Titanium, Inconel) → Choose a larger vise for better rigidity and holding power or utilize the 45-degree dovetail integrated into all standard vise hard jaws.

Workholding Density & Fixturing

Single-Part Machining? → A standard vise like the V562X offers the best versatility.

Multiple-Part Setups? → Use smaller vises in a high-density setup to increase throughput.

Automation & Palletization? → Consider a vise compatible with the RockLock™ Quick-Change System for fast swaps.

Yes, 5th axis vises can be used in the EDM environment. We have many customers that move vises from the mill to the EDM. All 5th Axis vises are built from hardened tool steel. Most models are coated with PVD or black oxide. We recommend that customers who utilize 5th axis vises inside the EDM do not leave them in the tank while not in operation. Properly drying the dovetail fixtures after they are removed from the EDM will prevent rusting.

Yes, most of 5th Axis vises were designed and optimized around automation systems. The self-centering vises can be mounted from the top down or used with the RockLock™ quick-change system. Utilize the 3D machine configuration tool to figure out what vise works best for your application.

All 5th Axis self-centering vises feature industry standard 52mm or 96mm pull stud spacing. This means they are RockLock™ ready. It also means that all vises are compatible with competitive systems utilizing the 52mm and 96mm pull stud spacing. The line of steel vises can also be directed mounted from the top down like a traditional vise using standard socket head cap screws and dowel locators. The dowel pins are removeable so if you run into an application where you need to direct mount the vise to the t-slot table, you can simply remove the dowel pins. We recommend using the dowel pins when mounting the vises onto a subplate or pallet.

Replacement Parts

-

$150.00

You May Also Like

-

$32.50

-

$59.00

-

$99.00

No Comments yet!