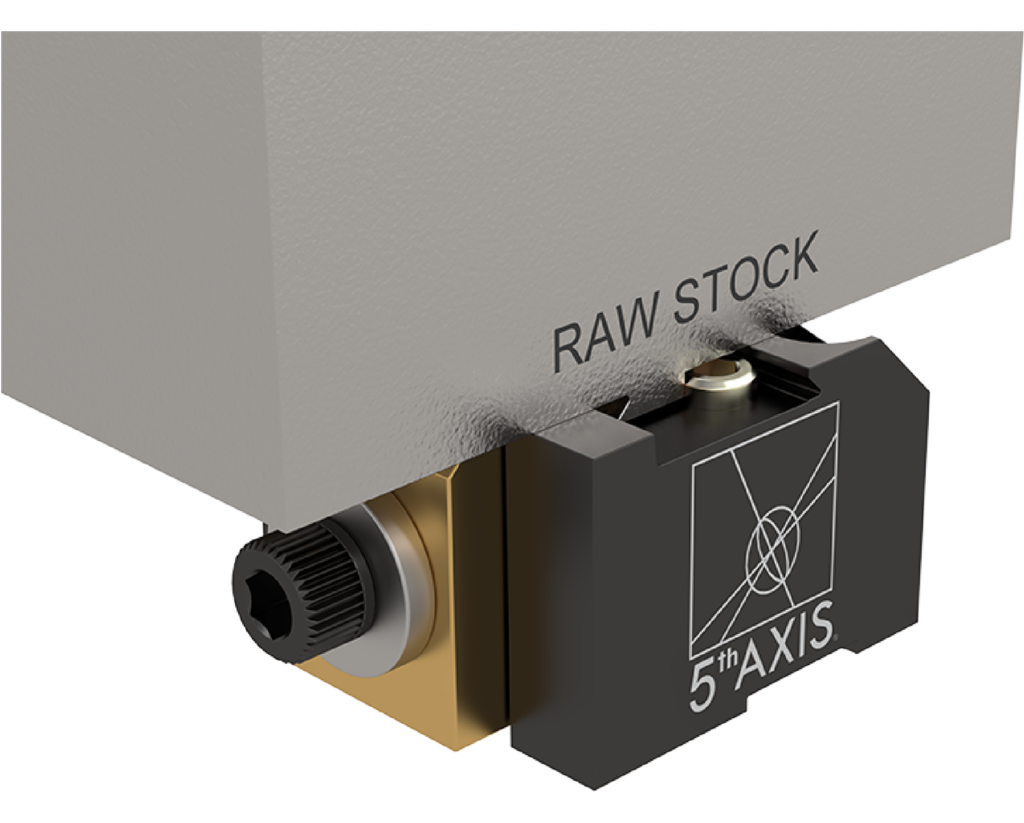

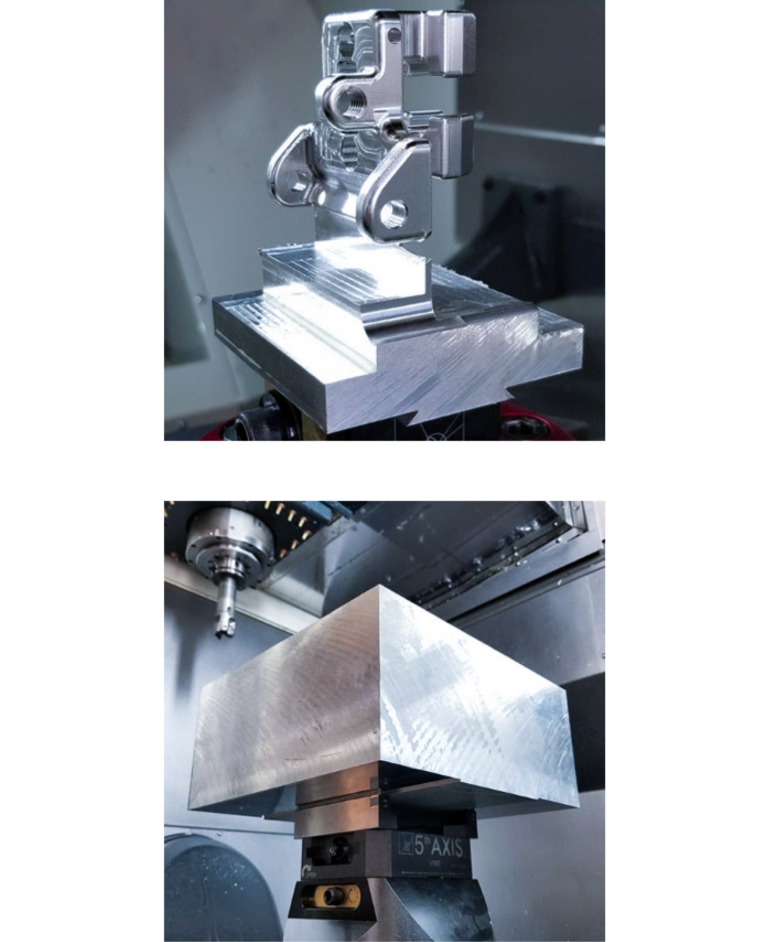

Locating / Stop Pin For Accuracy

A precision locating pin ensures the stock is centered in the fixture while ensuring the stock cannot be forced out of the fixture during machining.

The locating pin also provides high repeatability for in process inspection / movement from machine to machine.