Automation Hardware

Simplified

Robot Compatible Tooling

Pneumatic

Grippers & Chucks

Shelving & Storage

Robust Automation Hardware

RockLock™ automation hardware features industry standard 52mm and 96mm spacing. Pallet loading without the need for a pallet!

The benefit of fixture exchange is the robot programming. Because the robot is always picking up from the same point, there is no need for different grippers or changing the robot program based on individual parts.

Transport Cleats

Low profile cleats are offered in two weight capacities 12kg and 25kg. Create new fixtures or easily retrofit and add to new top tooling setups to your project with ease.

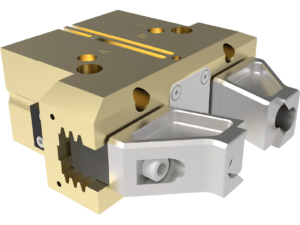

Pneumatic Chucks

Pneumatic RockLock™ receiver chucks come with industry standard 52mm or 96mm mounting, along with bottom or side air-port options. Lifters on the unit assist robot in picking and placing the tooling, and can also provide a burst of clean air to remove chips.

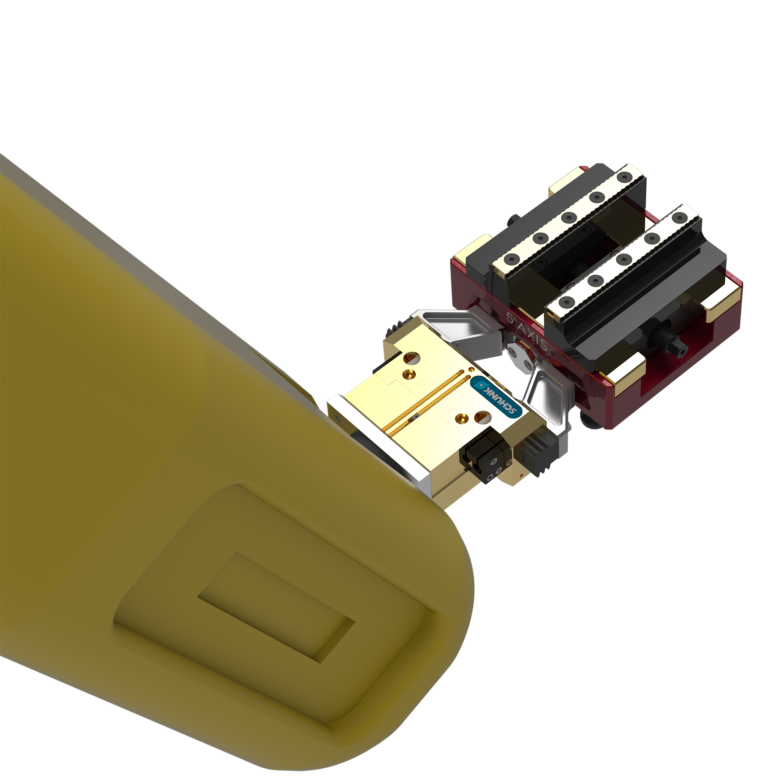

Parallel Grippers

5th Axis grippers are offered in 12kg and 25kg options compatible with the low profile cleats and RockLock™ Products. The grippers have a high quality Schunk body and 5-axis machined hardened gripper fingers for durability.

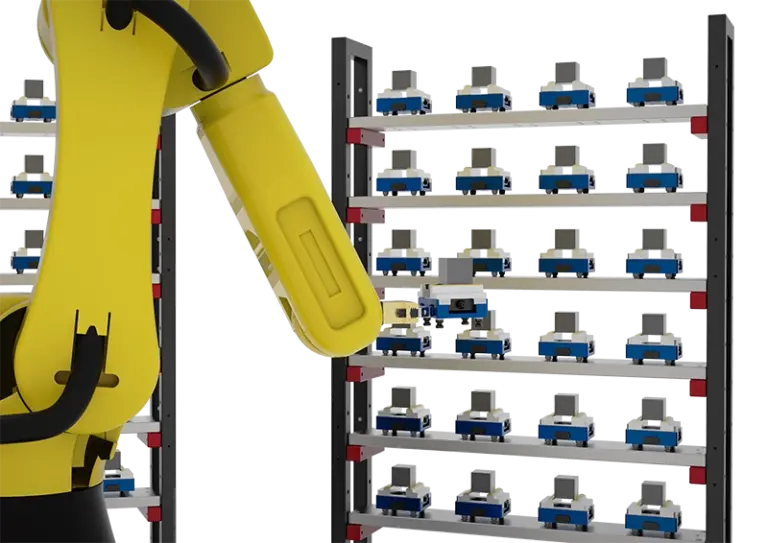

Rack & Shelf Kits

Our automation rack and shelf kits are simple to assemble and flexible by design, making it easy to customize your setup. The shelves are reversible to fit 52mm and 96mm RockLock™ products. Create a rack and shelf kit that is customized for your manufacturing needs.

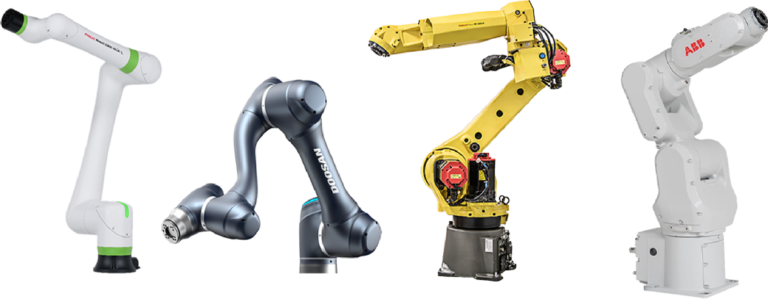

Universal Robot Compatibility

5th Axis hardware is built to be universal and compatible with the most popular industrial robots on the market today.