In the world of modern manufacturing, where efficiency and precision are non-negotiable, traditional tombstones have been a reliable workholding solution. However, they come with their fair share of limitations that can hinder productivity, increase setup time, and restrict access to workpieces. Enter 5th Axis RockLock Tombstones, a game-changing innovation that’s reshaping the manufacturing landscape.

The Challenge with Traditional Tombstones

Traditional tombstones have long been the go-to choice for manufacturers. But they aren’t without their challenges:

- Tool Change & Set-Up Time: Swapping tools or setting up new workpieces on traditional tombstones can be a time-consuming process. In high-volume production environments, every minute counts.

- Limited Workpiece Size and Shape: The design of traditional tombstones can limit the size and shape of workpieces that can be accommodated, which can be a significant constraint for diverse manufacturing needs.

- Limited Workpiece Accessibility: When tool access is required from multiple angles, traditional tombstones may limit access to certain areas of the workpiece, posing a challenge to machining processes.

The Solution: 5th Axis RockLock Tombstones

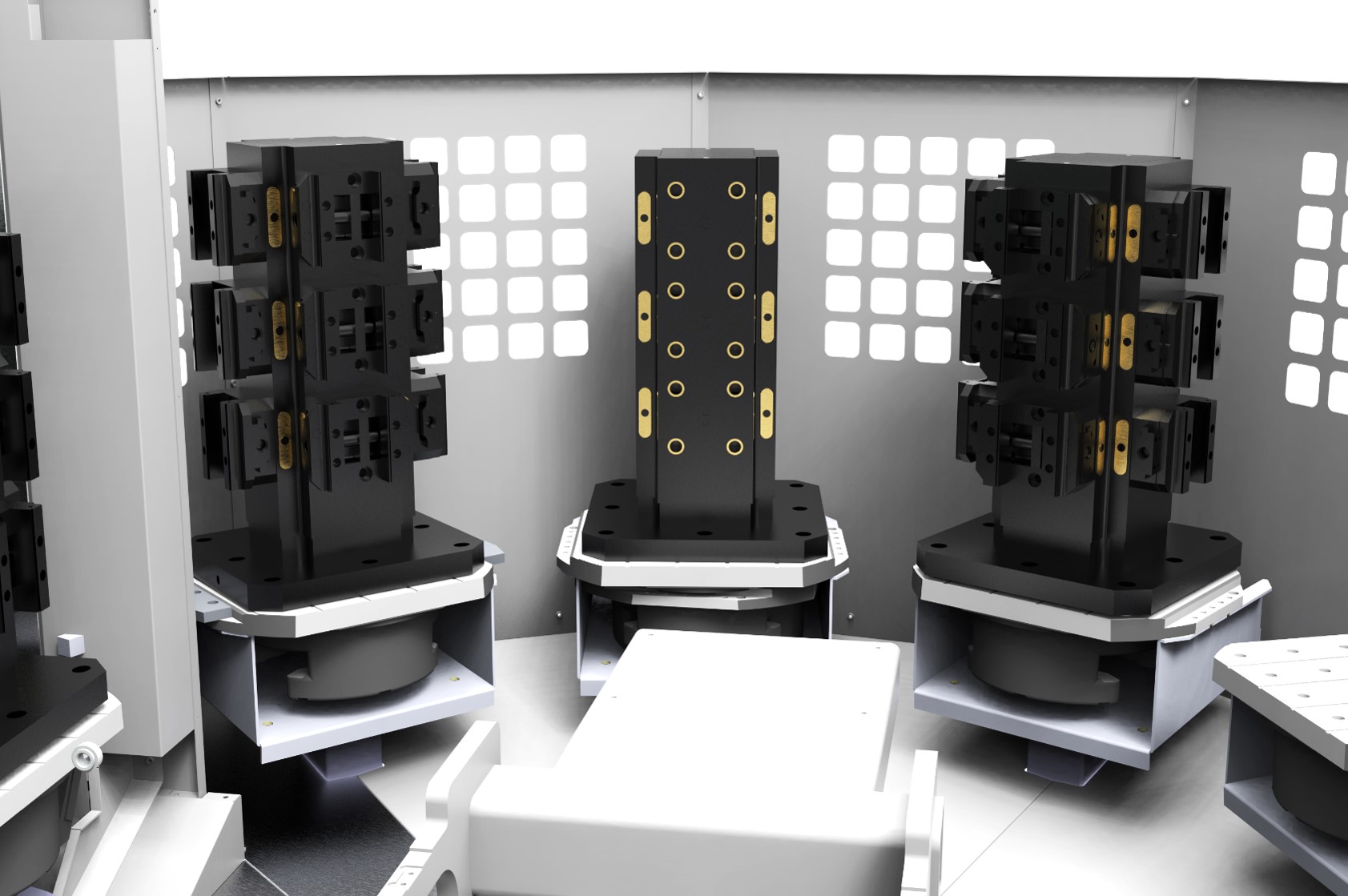

To overcome these challenges and revolutionize the machining process, manufacturers are turning to tombstones with a fully integrated zero-point system, and that’s precisely what 5th Axis RockLock Tombstones offer.

RockLock Integration for Precision and Speed

5th Axis RockLock Tombstones bring a host of advantages to the table:

- Precision Repeatability: RockLock integration ensures precision repeatability within seconds. Forget about struggling with multiple cap screws or custom tramming. It’s all about speed and accuracy.

- Flexibility: The flexibility of RockLock means these tombstones are compatible with various top tooling options, including vises, collet holders, fixture plates, and dedicated tooling. Add pull studs, and you’re good to go.

- Improved Workpiece Accessibility: With the versatility of RockLock Tombstones, you can opt for top tooling options like dovetail holders, enhancing access to the workpiece. This, in turn, reduces the number of operations and handling steps.

What Sets 5th Axis Apart?

The standout feature of 5th Axis RockLock Tombstones is that they are the only commercially available tombstones with FULL zero-point integration. Unlike other brands that require stacking multiple components to add a zero-point interface and cost 3 times more, 5th Axis delivers an integrated solution. This not only saves on costs but also preserves valuable machining space.

5th Axis RockLock Tombstones are reshaping the manufacturing landscape. They address the limitations of traditional tombstones head-on, offering precision, flexibility, and improved accessibility. With RockLock Tombstones, you can reduce setup times, increase efficiency, and unlock new levels of productivity in your machining processes.

Stay ahead of the curve with 5th Axis – where precision meets innovation.

Explore 5th Axis RockLock Tombstones for your manufacturing needs here.